Physical Principle of Ultrasonic Thickness Testing, and Some Facts on This Testing Method

Like other non-destructive testing methods, ultrasonic thickness testing is conducted without causing damage to test materials.

In ultrasonic thickness testing, ultrasound is transmitted into the test piece, it propagates through the test material in the form of waves, and, reaching an acoustic boundary, ultrasonic waves are partly reflected back and the remainder of them continue to pass through.

The distribution of the reflected and transmitted sound energy is affected, inter alia, by the degree of the acoustic hardness of the materials on the two sides of an acoustic boundary, incident angle, and the type and frequency of the applied ultrasonic waves.

Applications and Process of Ultrasonic Thickness Testing

The thickness of any material through which ultrasound is able to propagate at a given speed, approximately at constant speed of sound, can be measured, however there are materials which cannot be measured by using this testing method, as large-scale scattering and attenuation of ultrasound make it impossible to obtain accurate measurement results.

Our qualified inspectors select the non-destructive testing method most appropriate to the test material and the properties to be tested.

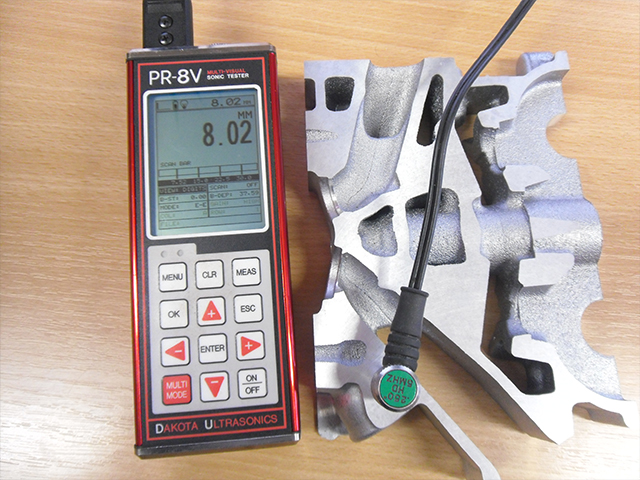

Different thickness testers are used for testing properly prepared surfaces in ultrasonic thickness testing. Such equipment produces ultrasonic waves necessary for testing and, fitted with an appropriate transducer and by using couplant, can detect the reflected ultrasonic signals.

Appropriately calibrated gauges used in ultrasonic thickness testing enable the accurate detection and measurement of the location of the reflecting surface that causes the reflection of ultrasonic waves and the amount of reflected ultrasound energy.

Factors Affecting the Effectiveness of Ultrasonic Thickness Testing and Special Cases of Testing

In ultrasonic testing of the thickness of test surfaces accessible from one side only, remaining wall thickness can accurately be measured on the surface beneath the transducer.

As in most non-destructive material testing, it is particularly important in thickness testing as well to properly prepare the test surface and calibrate the gauge according to test properties. All this increases the accuracy of ultrasonic thickness measurement. Wall thickness can accurately be measured through a thick paint layer in exceptional cases, however special gauges and a high degree of competence are needed for that.