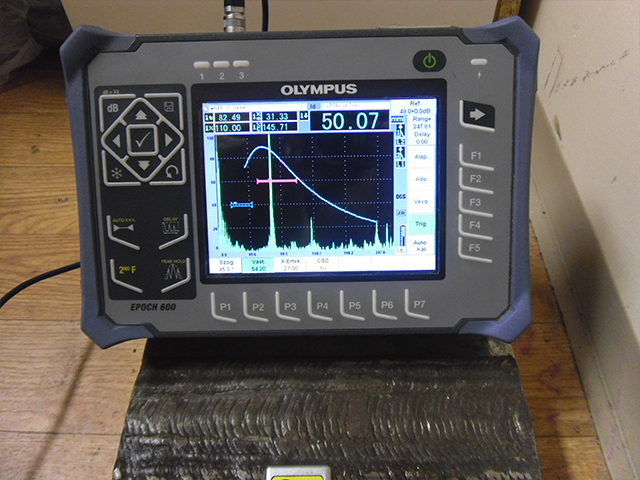

Ultrasonic Testing (UT) — High-Level Expertise and Wide Experience

What is ultrasonic testing (UT)?

Ultrasonic testing (UT) is one of the most widely used non-destructive testing method and utilises ultrasonic waves transmitted to a test piece.

Due to the different acoustic properties of materials, this test method reveals the location and size of possible discontinuities in the object or material tested.

In summary, ultrasonic testing (UT) method is used to detect volumetric and planar discontinuities in the tested components.

Numerous types of techniques can be used in ultrasonic testing (UT): pulse-echo (reflection) method, through-transmission technique, or time-of-flight diffraction technique.

Advantages of Ultrasonic Testing (UT)

This non-destructive testing method provides instantaneous results. It is sensitive to planar discontinuities, and images can be produced with automated systems.

Basic Principles of Ultrasonic Testing (UT)

The properties of ultrasonic waves are utilised in ultrasonic testing (UT); namely, how ultrasonic waves transmitted into a test piece propagate through the material tested, and to what extent ultrasonic waves are transmitted and to what extent they are reflected at an acoustic boundary. The proportion of the reflected and transmitted sound energy is affected, inter alia, by the acoustic hardness of the materials on the two sides of the acoustic boundary, incident angle, boundary geometry, and the type and frequency of the sent ultrasound energy.

Transducers used in ultrasonic testing (UT) generate ultrasound energy necessary for conducting the tests and detect the ultrasound signals reflected at a boundary. The cleaner and more even the test surface is, the more accurate test results are obtained; correct surface preparation is thus essential in ultrasonic testing (UT).